In today’s fast-paced manufacturing industry, injection molding stands as one of the most crucial processes for producing a wide range of plastic products. Behind this technology lies the craftsmanship of injection mold manufacturers, who blend art and science to create precision molds that enable the mass production of everything from household items to automotive components. In this article, we will delve into the world of injection mold manufacturing, exploring its significance, techniques, and the key factors that make a successful injection mold manufacturer.

The Significance of Injection Mold Manufacturing

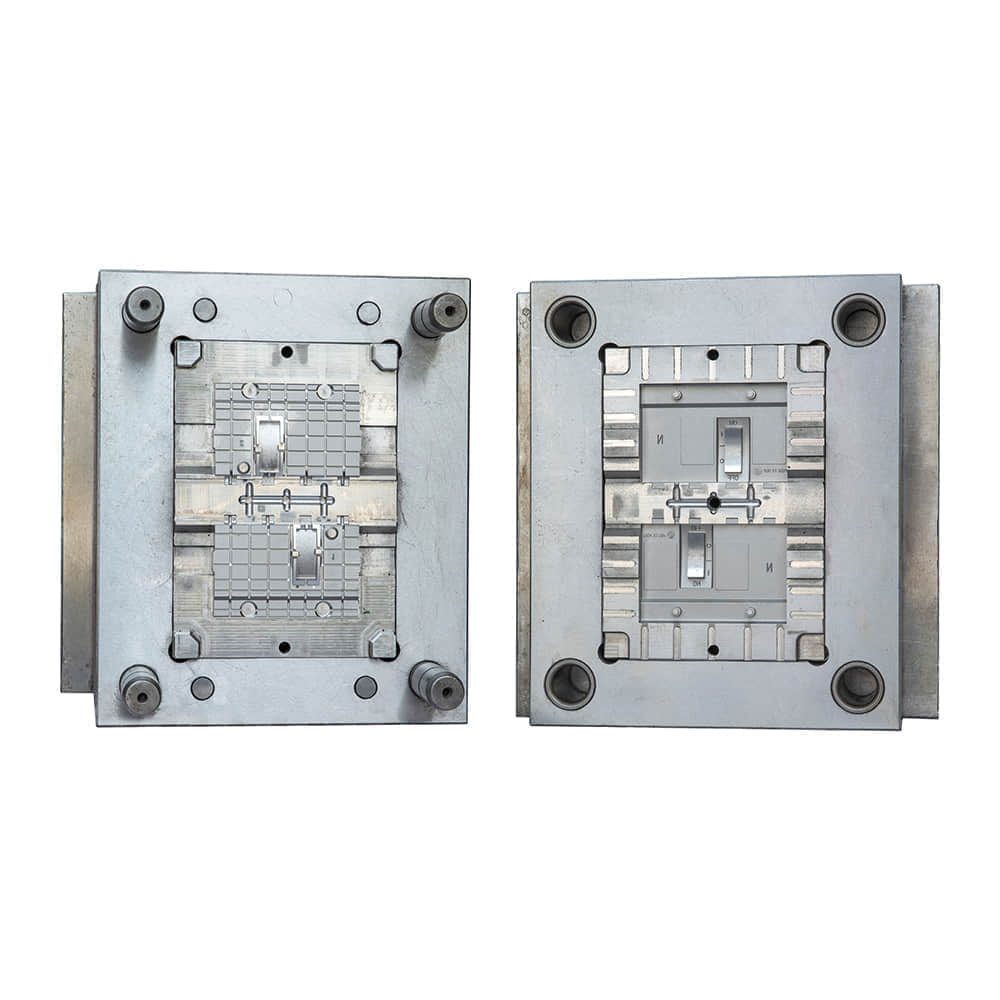

Injection mold manufacturing is the cornerstone of modern manufacturing. It plays a pivotal role in industries such as automotive, consumer electronics, medical devices, and packaging. The process involves melting plastic pellets and injecting the molten material into a meticulously designed mold. Once cooled and solidified, the mold is opened, revealing a perfectly shaped plastic part. This efficient and cost-effective method allows for high-volume production with remarkable precision and consistency. The significance of injection mold manufacturing lies in its ability to transform design concepts into tangible products. Whether it’s the sleek dashboard of a luxury car or the housing of a smartphone, the molds used in these processes are the unsung heroes behind every successful product launch. Manufacturers rely on injection mold makers to produce molds that are not only accurate and durable but also optimized for efficient production.