In the world of manufacturing, precision is the key to success. When it comes to creating intricate and highly detailed metal parts, metal stamping dies play a pivotal role. These tools are the unsung heroes behind the scenes, responsible for shaping raw metal into the components that power countless industries. In this article, we delve into the world of Metal Stamping Die OEM (Original Equipment Manufacturer) companies, exploring their significance, innovation, and the impact they have on our everyday lives.

The Craftsmanship Behind Metal Stamping Dies

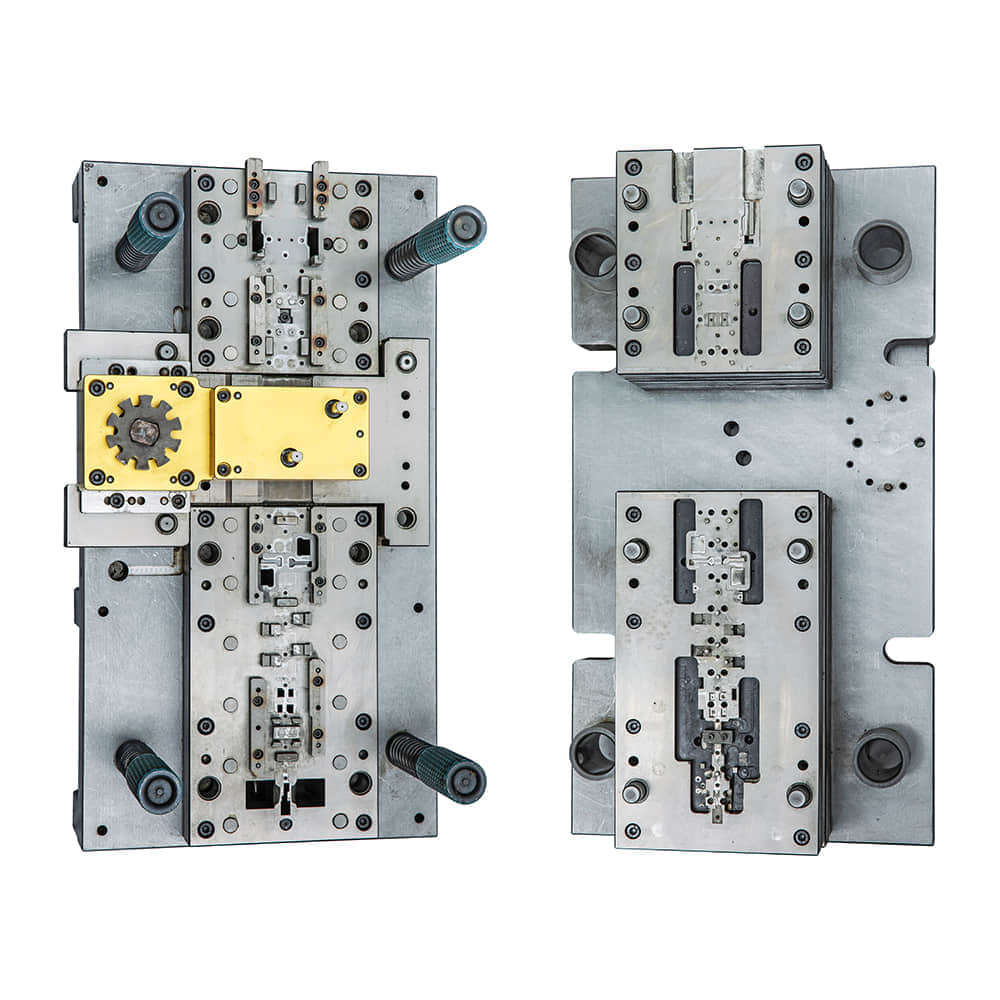

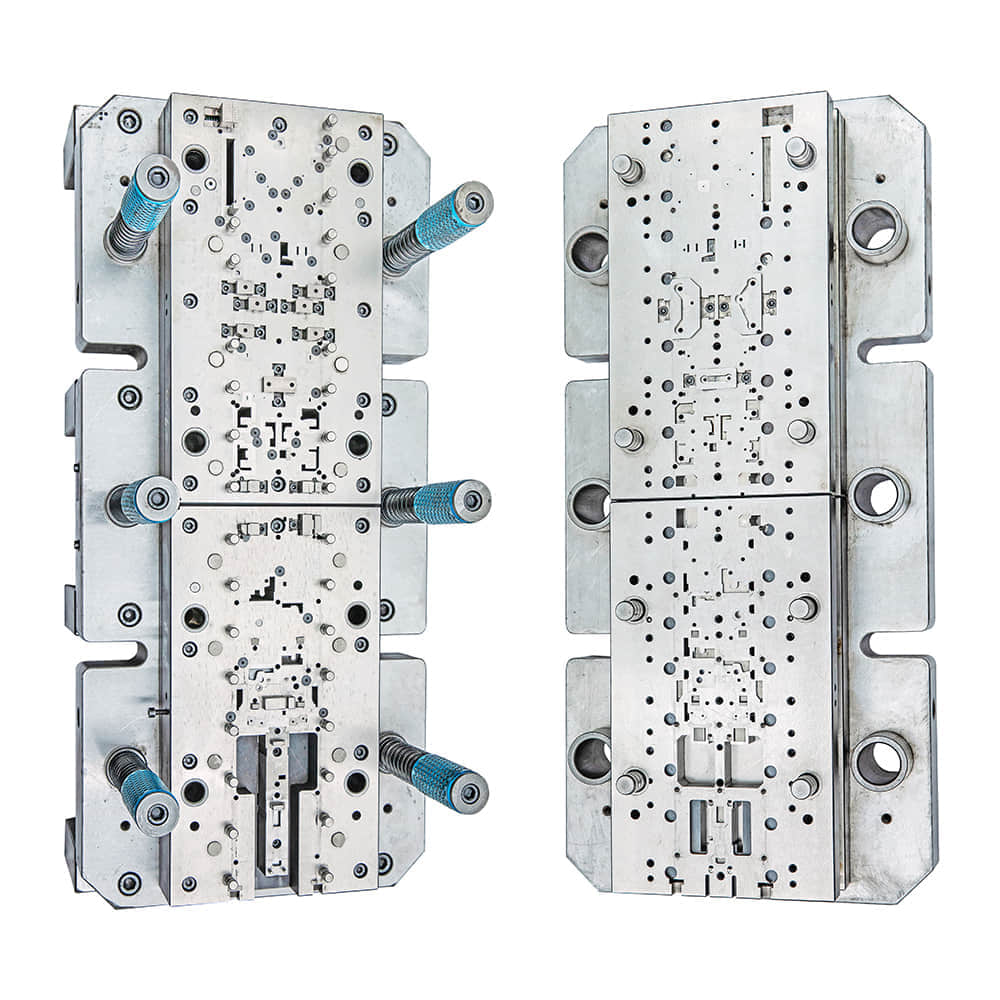

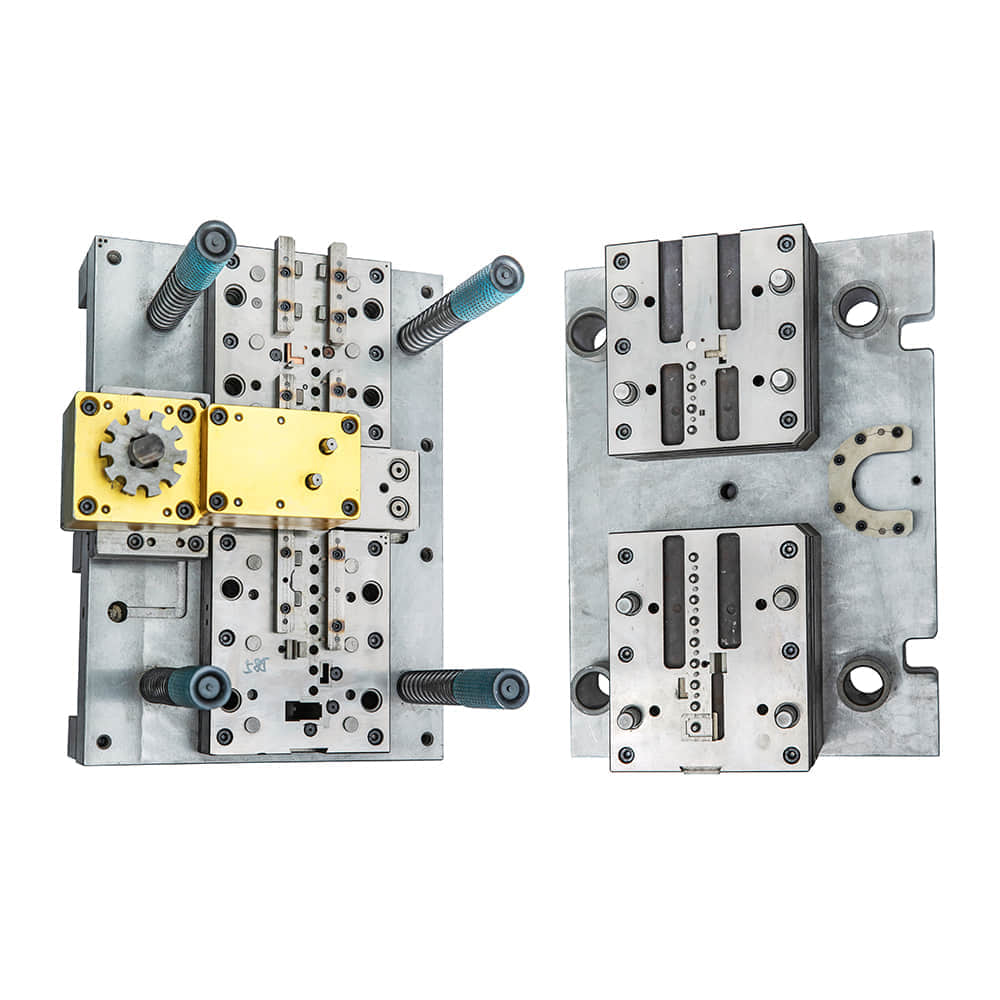

Metal stamping dies are meticulously crafted tools, engineered with utmost precision. These dies are used to cut, form, and shape metal sheets into various components, from automotive parts and electronics to household appliances. The importance of precision in this process cannot be overstated, as even the slightest deviation can result in faulty products or compromised safety. OEM manufacturers specializing in metal stamping dies are artisans in their own right. They combine cutting-edge technology with years of expertise to design and build dies that meet the unique specifications of their clients. The result is a tool that can produce thousands or even millions of identical parts with remarkable consistency. Innovation in Metal Stamping Die Manufacturing The world of metal stamping die manufacturing is not static; it’s a realm where innovation thrives. OEM manufacturers constantly push the boundaries of what is possible, seeking to improve efficiency, reduce waste, and enhance the quality of stamped parts. One of the most notable innovations in recent years is the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) software. These tools allow engineers and designers to create highly complex die designs with incredible precision. Simulations help identify potential issues before production even begins, saving both time and resources. Additionally, advancements in materials science have led to the development of more durable and wear-resistant die materials. This not only extends the lifespan of the dies but also contributes to higher-quality end products. The Ubiquitous Impact of Metal Stamping Dies Metal stamping dies are everywhere, even if you don’t see them. They are the silent heroes behind the scenes, enabling the mass production of countless products we rely on daily. From the chassis of your car to the keyboard on your laptop, metal stamping dies have played a role in shaping the modern world. In the automotive industry, metal stamping dies are responsible for creating the intricate parts that make up a vehicle’s body and engine components. In the electronics sector, they craft the tiny components found in your smartphone and other devices. In the medical field, metal stamping dies create the precise parts used in life-saving equipment. Sustainability and Metal Stamping Die Manufacturing As the world becomes more environmentally conscious, OEM manufacturers of metal stamping dies are also adapting to meet the demand for sustainable solutions. They are actively exploring ways to reduce waste in the stamping process, optimize material usage, and incorporate eco-friendly materials. In addition to improving sustainability in their own operations, these manufacturers are contributing to a greener future by enabling the production of more energy-efficient products. For example, metal stamping dies are used to create lightweight components for electric vehicles, reducing fuel consumption and greenhouse gas emissions. Conclusion Metal stamping die OEM manufacturers are the architects of precision in modern manufacturing. Their craftsmanship and commitment to innovation have a profound impact on industries across the board, from automotive to electronics and beyond. As they continue to push the boundaries of what is possible, we can expect even greater precision, efficiency, and sustainability in the world of metal stamping die manufacturing, shaping the products that define our future.