Thermoplastic Injection Molding: The Heart of Modern Manufacturing

In the dynamic world of manufacturing, thermoplastic injection molding stands as a cornerstone process, enabling the creation of a vast array of products with precision and efficiency. This article aims to delve into the fundamentals of thermoplastic injection molding, its applications, and the reasons why it remains a preferred choice for manufacturers across industries.

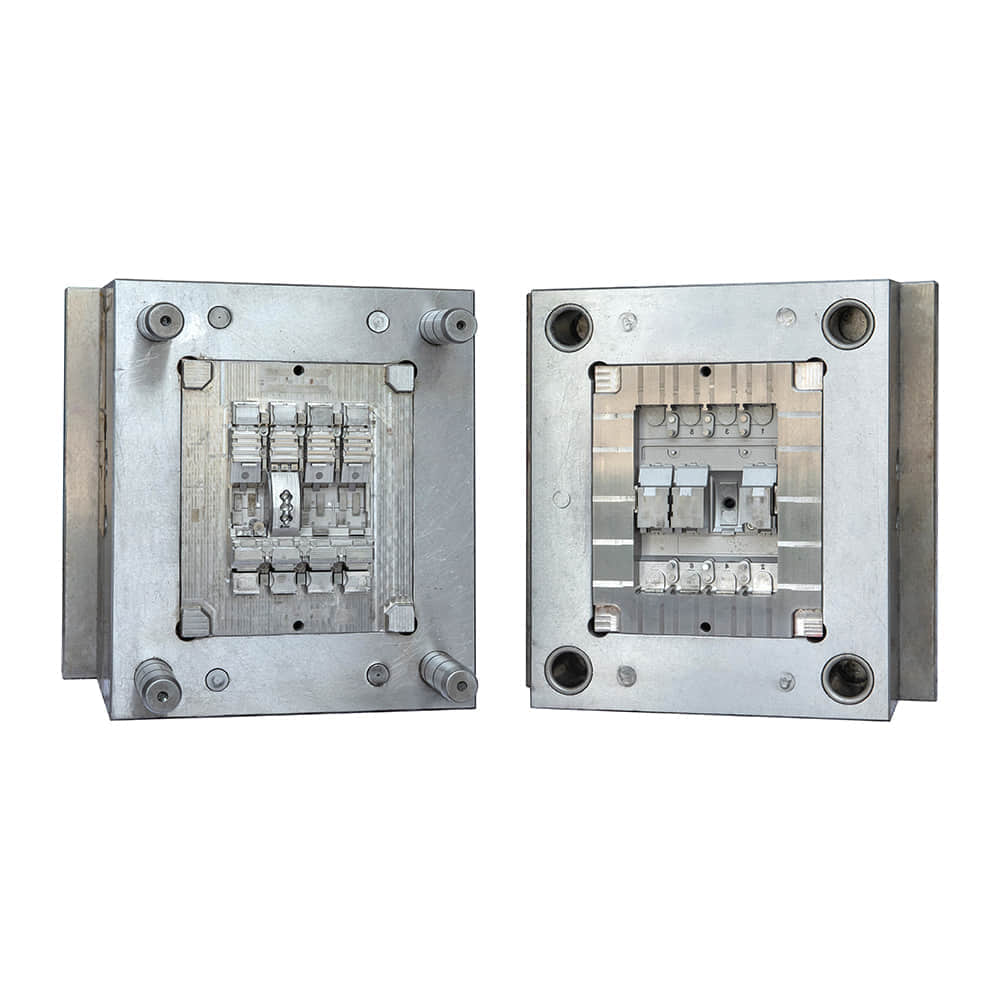

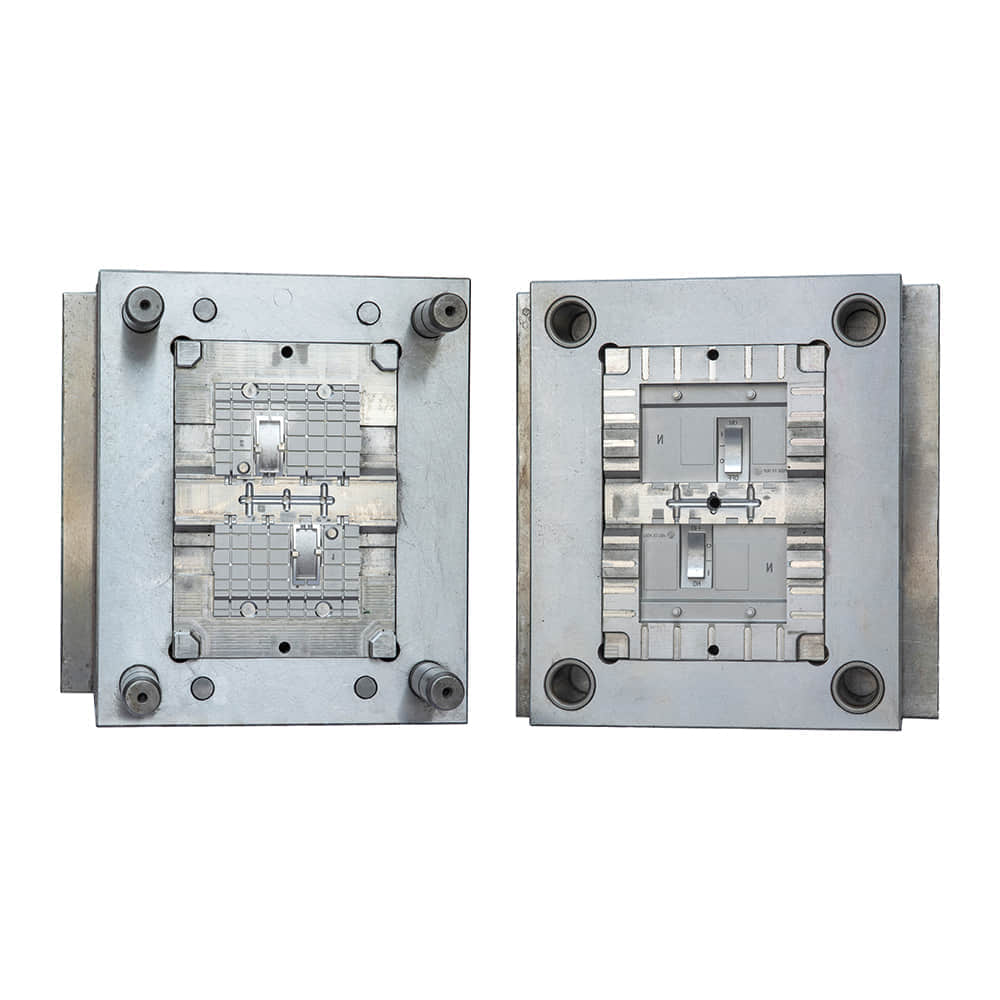

What is Thermoplastic Injection Molding? Thermoplastic injection molding is a manufacturing process that involves injecting molten thermoplastic material into a mold to create a desired shape or part. The process begins with the selection of an appropriate thermoplastic material, which is then heated to its molten state. This molten material is then injected into a mold, which has been specifically designed to create the desired shape. Once the material has cooled and solidified within the mold, the part is ejected, ready for further processing or use. Applications of Thermoplastic Injection Molding