Injection molding is a remarkable manufacturing process that has revolutionized the production of various plastic and metal components. This technique has become the backbone of countless industries, from automotive to consumer electronics, thanks to its versatility, efficiency, and precision. In this article, we will explore the world of injection molded parts, delving into its intricacies, applications, and the innovative technology behind it.

The Injection Molding Process

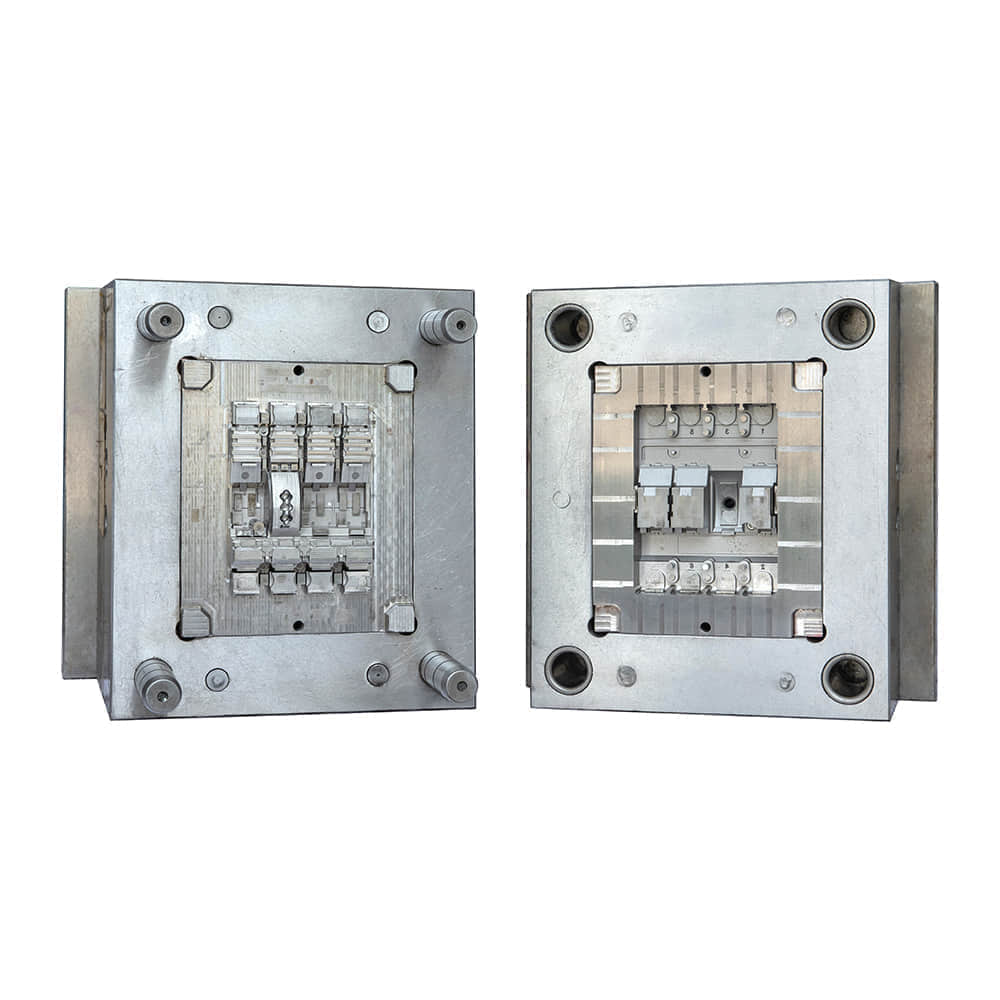

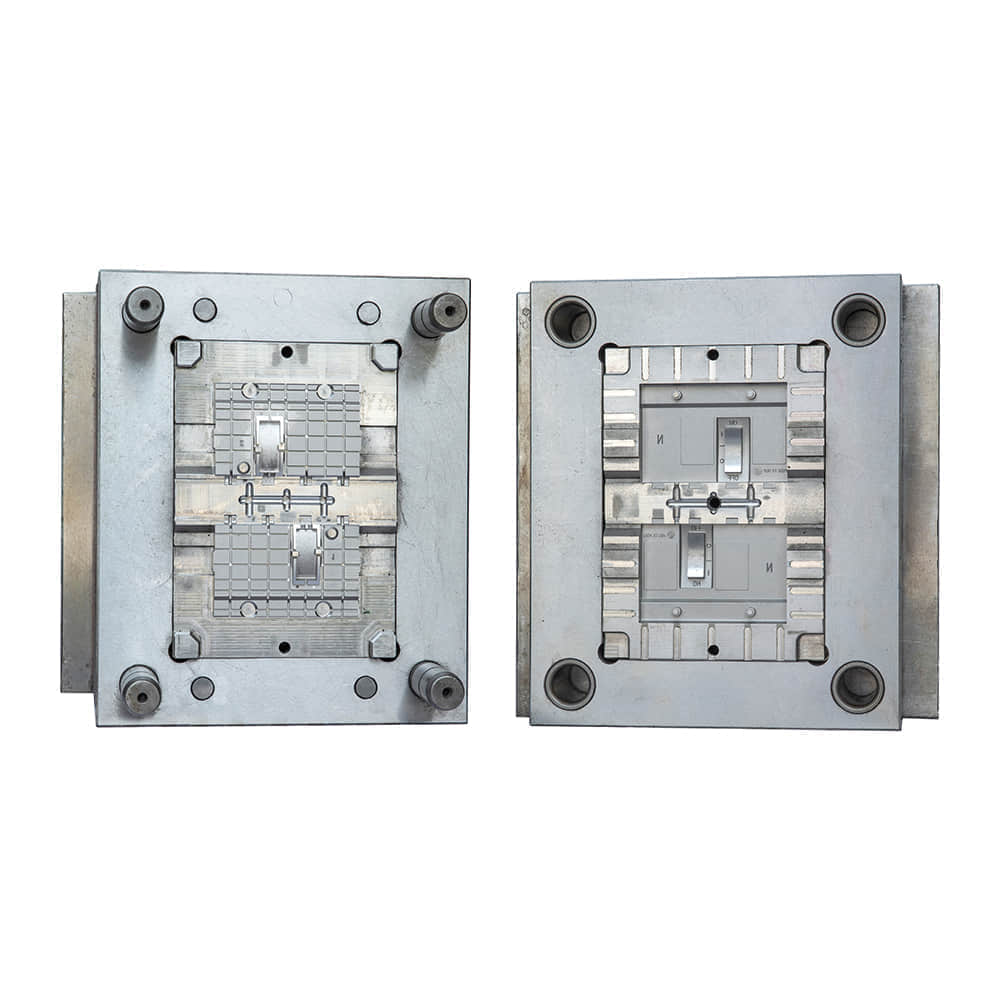

Injection molding is a highly sophisticated process that involves melting a chosen material and injecting it into a mold cavity. This mold, typically made of steel or aluminum, is designed with intricate details that define the final shape of the product. Once the molten material cools and solidifies, the mold is opened, revealing the finished part. The key to injection molding’s success lies in its precision. The molds are engineered with exceptional accuracy, allowing for the creation of complex shapes, tight tolerances, and consistent results. This precision is crucial in industries like aerospace and medical, where reliability and consistency are paramount. Materials in Injection Molding