文章:

Injection mold manufacturers play a pivotal role in the modern manufacturing industry, enabling the production of a wide range of plastic and metal components that are integral to countless products we use in our daily lives. In this article, we will delve into the world of injection mold manufacturing, exploring its processes, importance, and the impact it has on various industries.

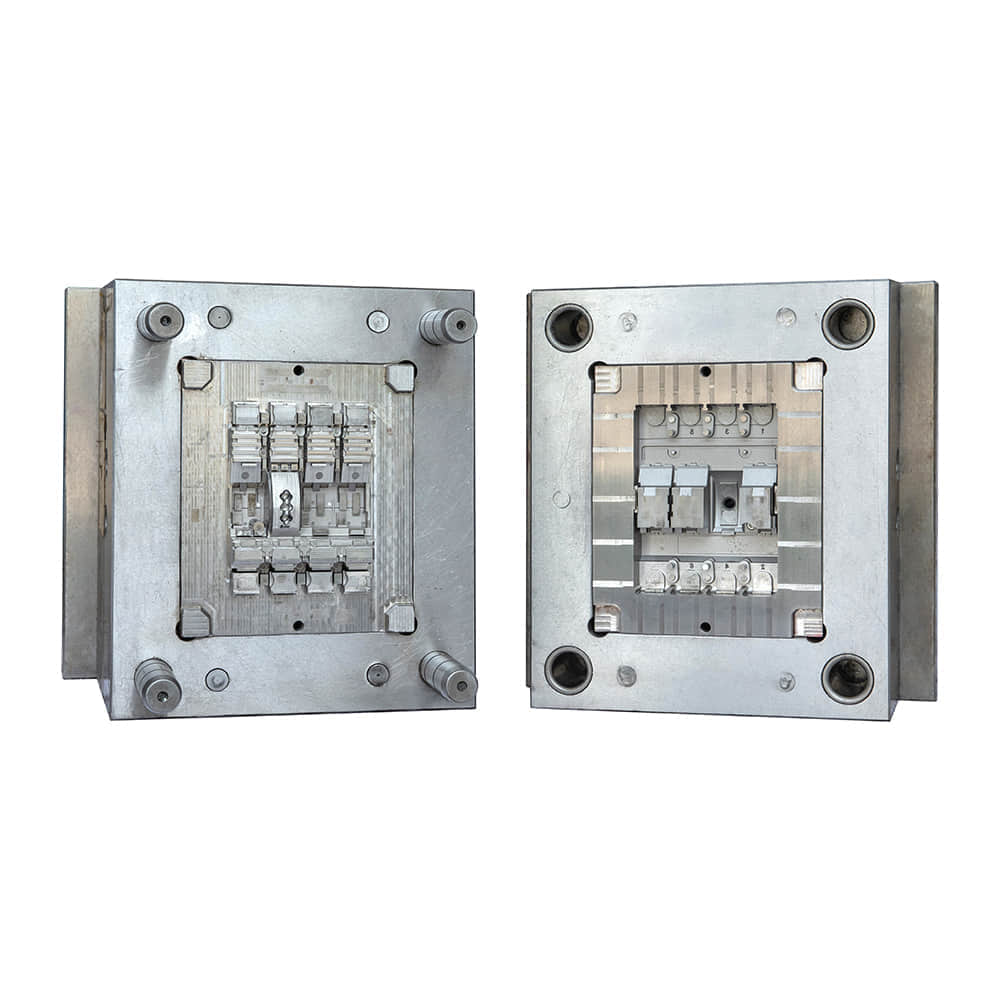

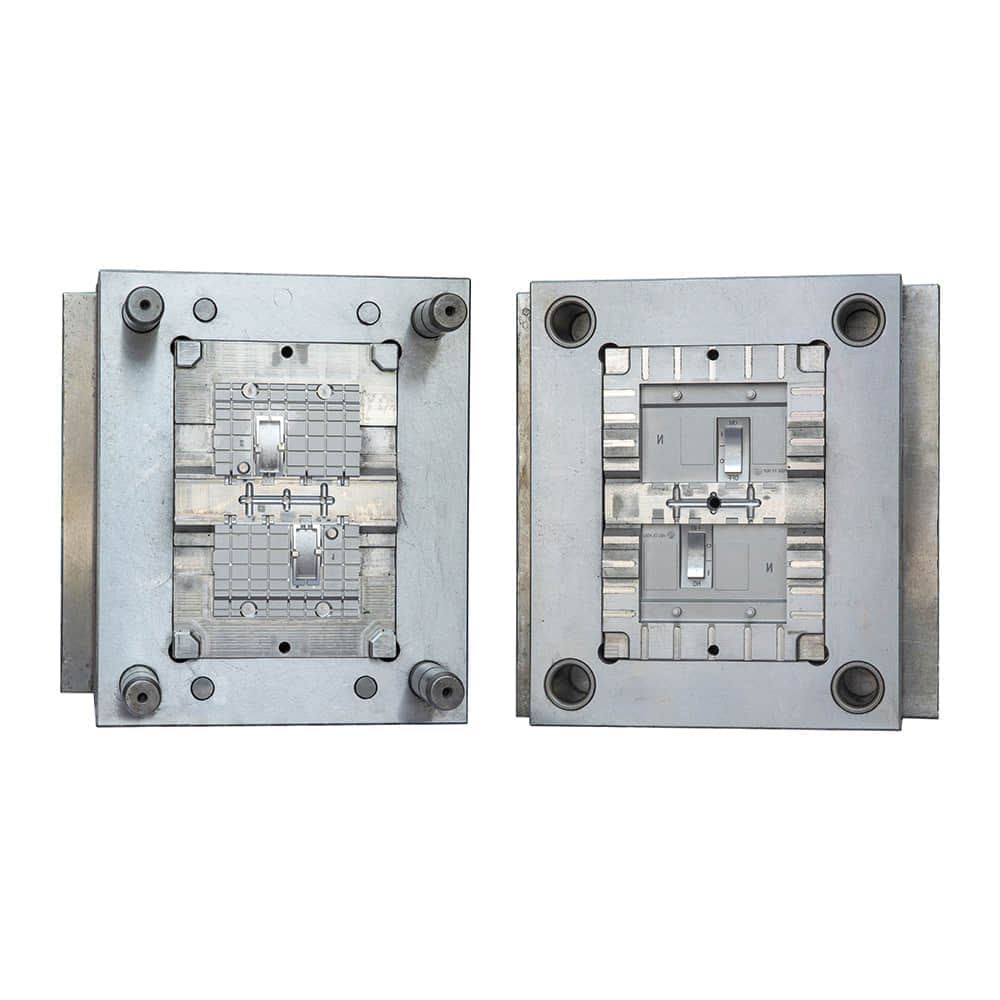

The Basics of Injection Mold Manufacturing Injection molding is a manufacturing process used to produce parts and products by injecting molten material into a mold cavity. Injection mold manufacturers are responsible for designing and creating these molds, which are essential for shaping materials such as plastic, rubber, and metal into specific forms. The process involves several key steps: Design and Prototyping:The journey begins with the creation of a mold design based on the product specifications. Advanced software is used to design the mold, ensuring precision and efficiency. Prototyping helps in testing and refining the design before mass production. Material Selection:Choosing the right material is crucial, as it impacts the final product’s properties, durability, and cost. Injection mold manufacturers work closely with clients to select materials that meet their requirements. Mold Fabrication:Skilled mold makers then fabricate the mold itself, often using precision machining techniques to create molds with high tolerances. This step demands meticulous attention to detail. Injection Molding:Once the mold is ready, it’s installed in an injection molding machine. Molten material is injected into the mold cavity, where it cools and solidifies, taking on the desired shape. Quality Control:Injection mold manufacturers perform rigorous quality checks to ensure the final products meet the specified standards. Any defects or imperfections are addressed promptly. The Significance of Injection Mold Manufacturers Versatility:Injection mold manufacturers cater to a wide range of industries, including automotive, aerospace, electronics, medical, and consumer goods. Their adaptability makes them indispensable to the global manufacturing ecosystem. Cost Efficiency:Injection molding offers cost-effective solutions for producing complex parts in large quantities. The initial investment in mold creation can be offset by the economies of scale achieved during mass production. Precision and Consistency:Modern injection mold manufacturing ensures a high level of precision and consistency in the produced parts. This reliability is crucial, especially in industries where safety and performance are paramount. Innovation:Injection mold manufacturers continually innovate in materials and processes, driving advancements in product design and functionality. This innovation contributes to the development of new technologies and products. Reduced Waste:Injection molding generates less material waste compared to other manufacturing methods, contributing to sustainability efforts. Many materials used in injection molding are recyclable, further minimizing environmental impact. The Impact on Various Industries Automotive Industry:Injection mold manufacturers supply components like dashboards, bumpers, and interior trims, contributing to the sleek designs and safety features of modern vehicles. Medical Devices:In the medical field, precision and sterility are paramount. Injection mold manufacturers produce components for medical devices, ensuring the highest quality and compliance with regulatory standards. Consumer Electronics:From smartphone casings to laptop parts, the consumer electronics industry relies heavily on injection molding to create sleek, durable, and functional products. Packaging:Injection molding plays a crucial role in producing packaging materials, such as bottles, caps, and containers, ensuring the protection and preservation of food and beverages. Aerospace:Injection mold manufacturers provide components for aircraft and spacecraft, where precision, reliability, and lightweight materials are essential. In conclusion, injection mold manufacturers are the unsung heroes of modern manufacturing, contributing to the production of countless products that enhance our lives. Their ability to create precise, reliable, and cost-effective components spans across industries, shaping the world around us and driving innovation forward. As technology advances and environmental concerns grow, injection mold manufacturing will continue to evolve, playing a vital role in the future of manufacturing.