Metal stamping die manufacturers occupy a pivotal position in the manufacturing industry, specializing in the creation of precision tools that transform metal sheets into desired shapes and sizes. These manufacturers not only possess the technical prowess to design and fabricate intricate dies but also contribute significantly to the efficiency and profitability of various industries.

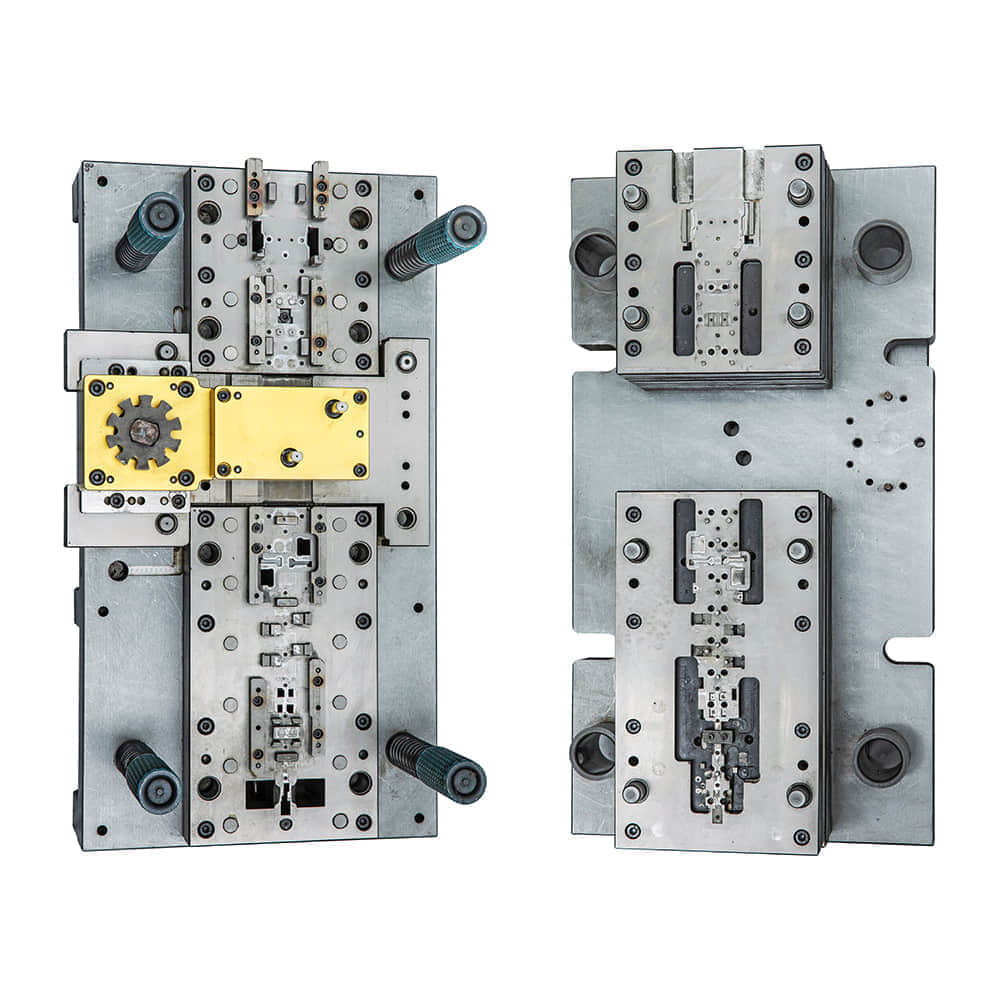

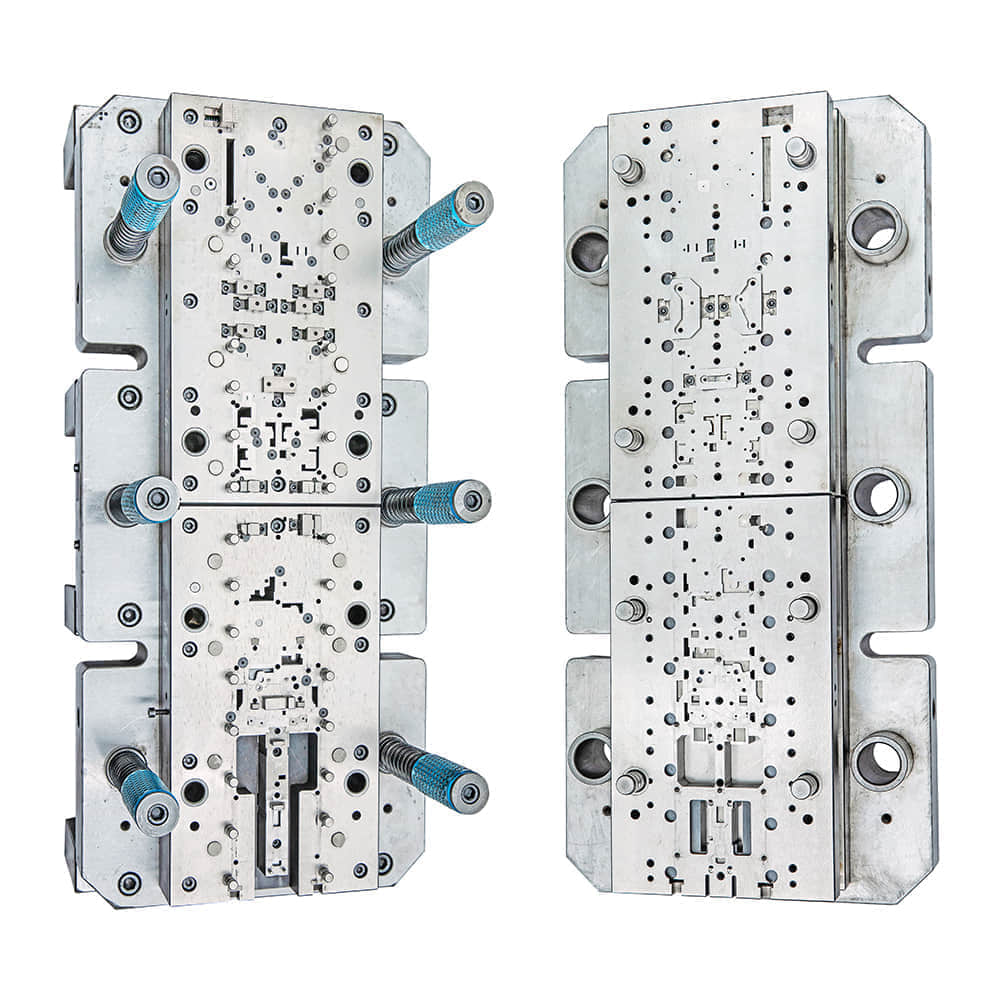

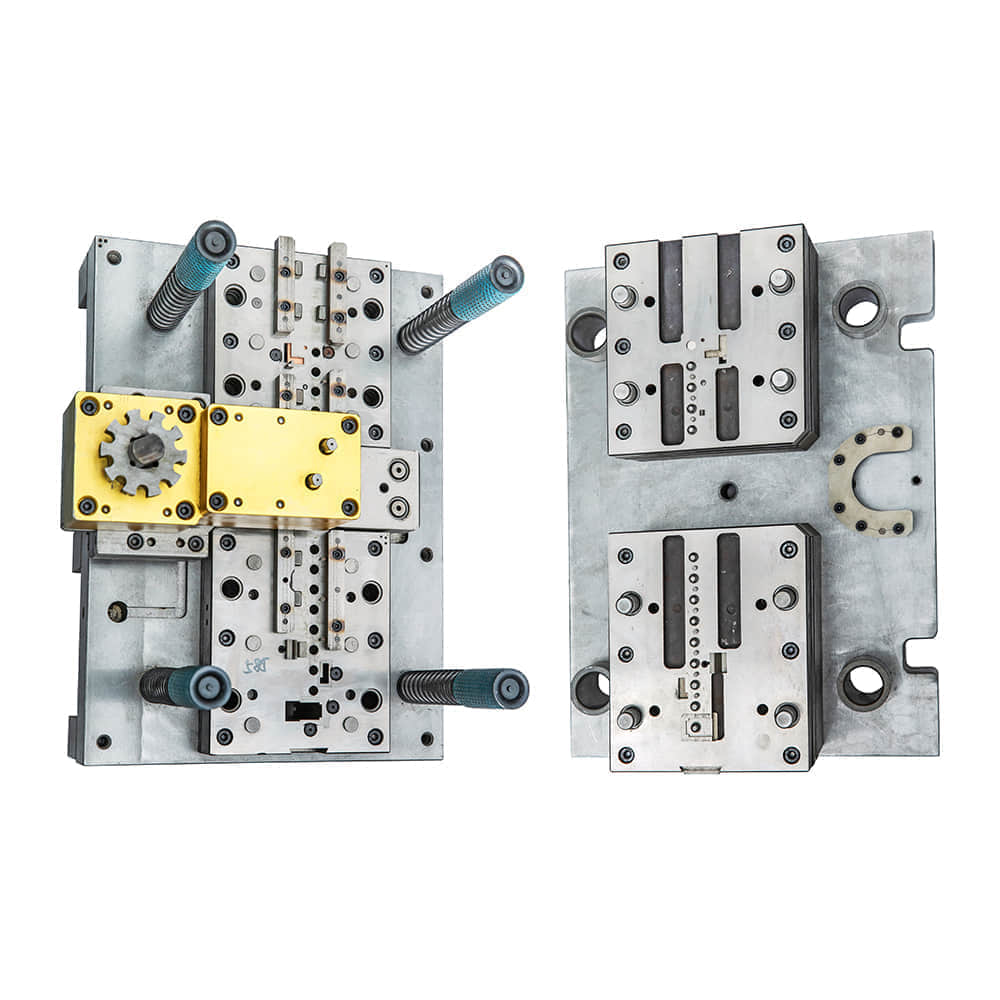

The core of any metal stamping operation lies in the die, a crucial component that ensures the accuracy and repeatability of the stamping process. Metal stamping die manufacturers are experts in understanding the intricate details of material properties, die design principles, and manufacturing processes. They leverage advanced CAD/CAM systems and precision machining equipment to create dies that meet exacting standards of quality and performance.

The manufacturing process begins with a thorough understanding of the customer’s requirements and the specifications of the desired product. The design team at these manufacturers then gets to work, creating a die design that optimizes material flow, reduces waste, and ensures the highest level of precision. This design is then translated into a physical die through a series of machining operations, including milling, grinding, and drilling. The materials used in die manufacturing are carefully selected based on their strength, wear resistance, and machinability. Common materials include tool steel, carbide, and ceramic, each with its own unique set of properties that make it suitable for specific applications. The choice of material is crucial in ensuring the longevity and performance of the die.