Metal stamping die is a crucial component in the manufacturing process of metal components, playing a vital role in converting raw metal sheets into finished products of desired shapes and sizes. In this article, we will explore the intricacies of metal stamping die, its significance in metal forming, and the advancements made in this field.

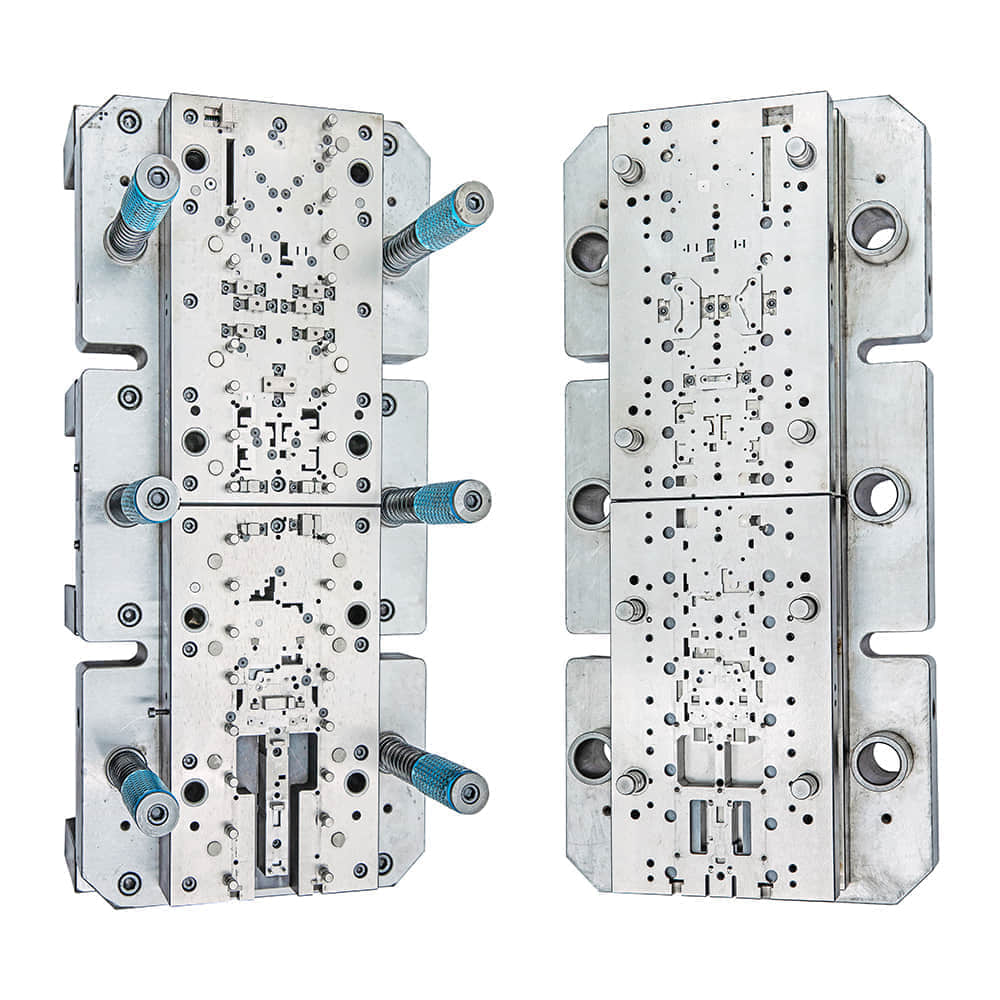

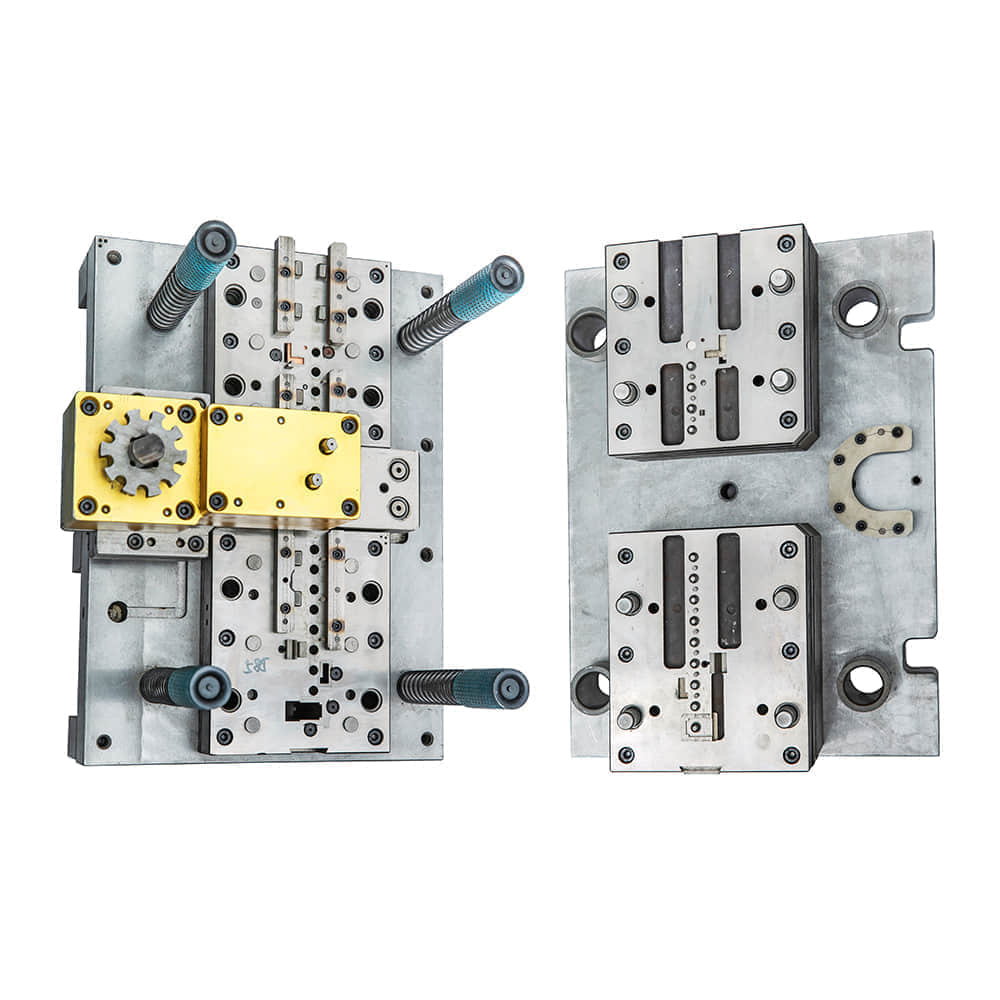

The metal stamping process involves the use of dies to stamp out precise shapes from metal sheets. These dies are typically made from high-grade steel or hardened tool steel due to their exceptional strength and wear resistance. They are designed with great precision, ensuring accurate replication of the desired shape. The dies undergo rigorous heat treatment and surface hardening to enhance their durability and longevity.

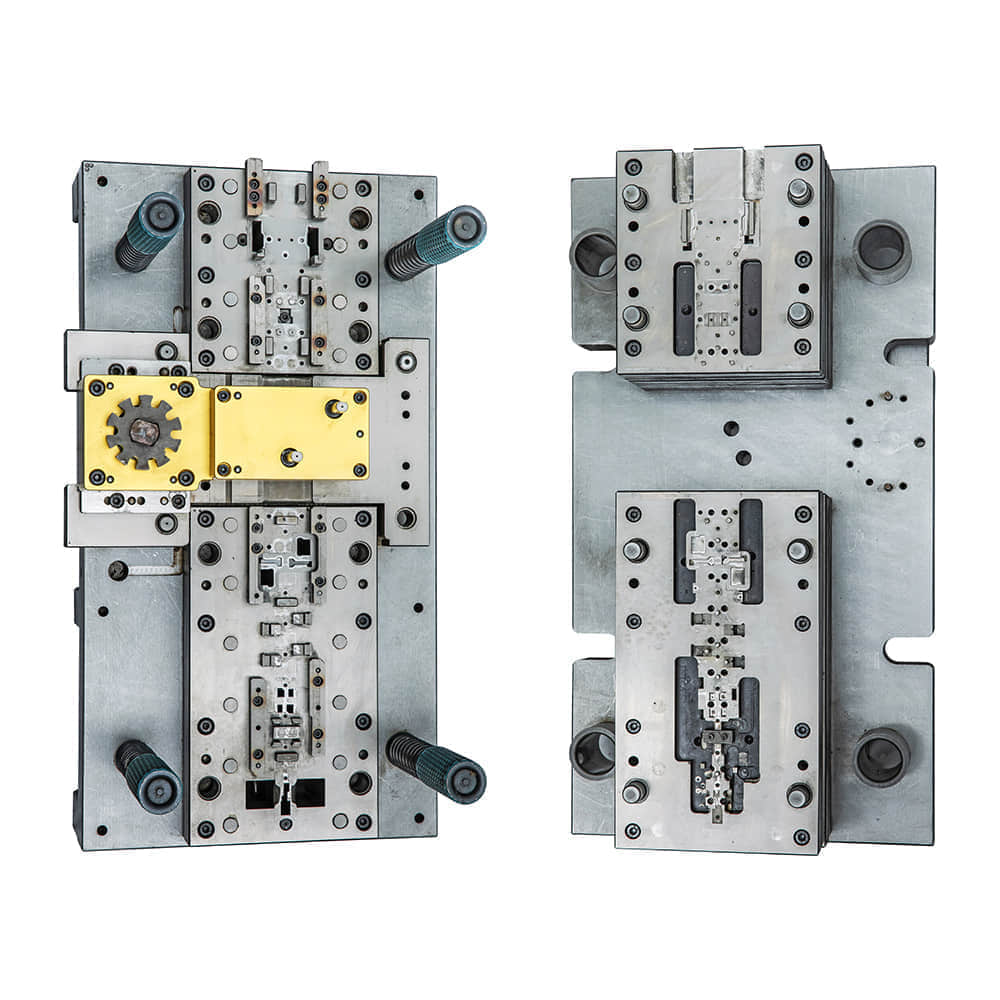

The metal stamping die consists of several key components. The male punch, also known as the upper die, is responsible for deforming the metal sheet into the desired shape. It is attached to a ram that provides the necessary force for punching. The female die, or lower die, acts as a counter-bore and supports the material during the stamping process. The guide rails ensure the precise alignment of the punch with respect to the die. The selection of the appropriate metal stamping die significantly impacts the quality and efficiency of metal forming. The die design should take into account various factors such as the type of metal being processed, the desired shape and thickness, and the required production volume. The choice of material for the die is crucial, as it must possess sufficient strength and wear resistance to withstand the repeated impact of the punch.