Metal stamping die, a critical tool in the manufacturing industry, plays a pivotal role in shaping and forming metal components. Its precision and durability ensure the high-quality production of various metal parts, ranging from automotive components to electronic devices. This article delves into the applications, processes, and future prospects of metal stamping die.

Metal stamping die finds its widespread application in various industries. The automotive industry, for instance, heavily relies on stamping dies to produce intricate parts like engine components and chassis pieces. The electronic industry also utilizes stamping dies to fabricate small and precise metal parts for electronic devices. Additionally, the aerospace industry demands the utmost precision and durability, making metal stamping die an indispensable tool for fabricating aircraft parts.

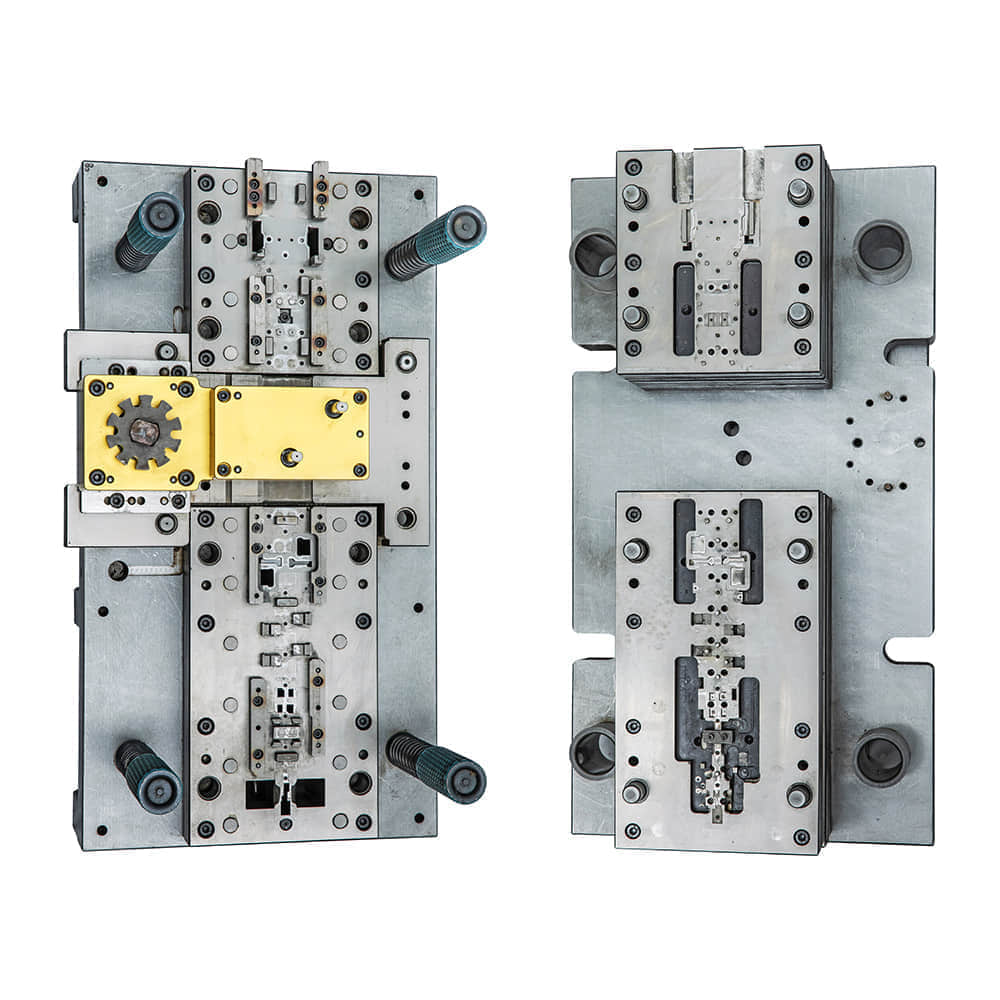

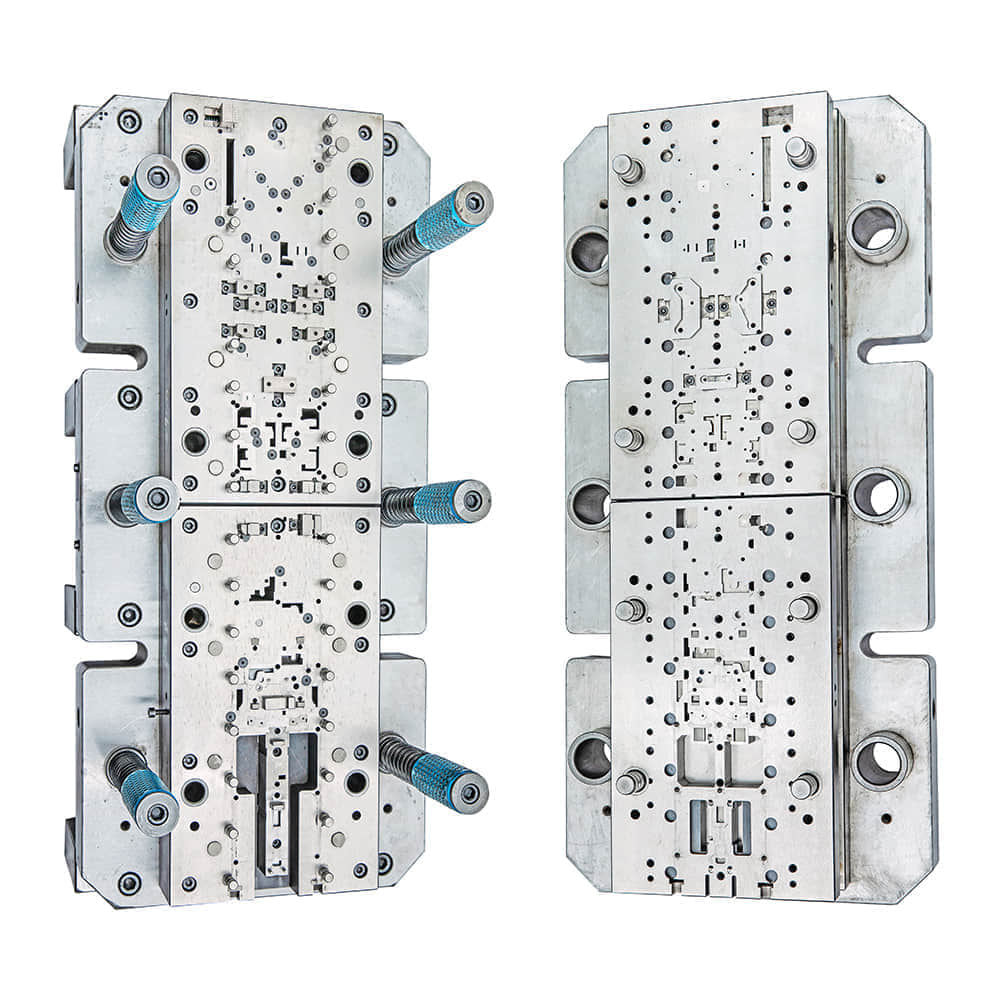

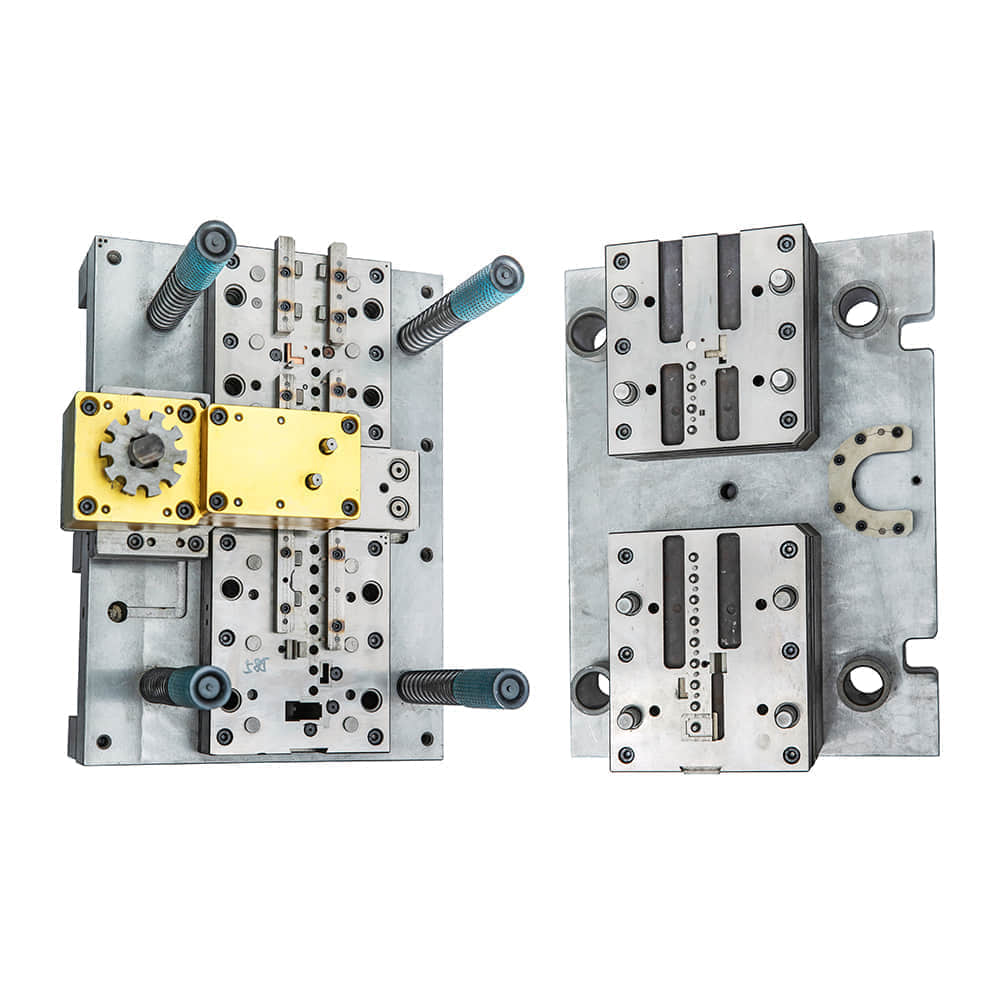

The process of metal stamping involves the use of a die, which is a precision-made tool with the desired shape of the final product. The metal sheet is placed between the die and a stamping press, which applies force to deform the metal into the shape of the die. The precision and quality of the stamping die directly impact the final product’s accuracy and durability. The manufacturing of metal stamping die requires a high level of skill and expertise. The die must be designed and fabricated with utmost precision to ensure the accuracy of the final product. The materials used for making the die are also crucial, as they must be able to withstand the high forces applied during the stamping process. Common materials used for making stamping dies include steel, carbide, and ceramic.