In the realm of manufacturing, precision and efficiency are paramount, especially in industries that require intricate parts and components. One of the critical players in this sector is the China metal stamping die manufacturer. These manufacturers specialize in producing metal stamping dies, which are essential tools used to shape and cut metal into desired forms. This article delves into the role these manufacturers play, the processes involved, and the advantages they offer to businesses globally.

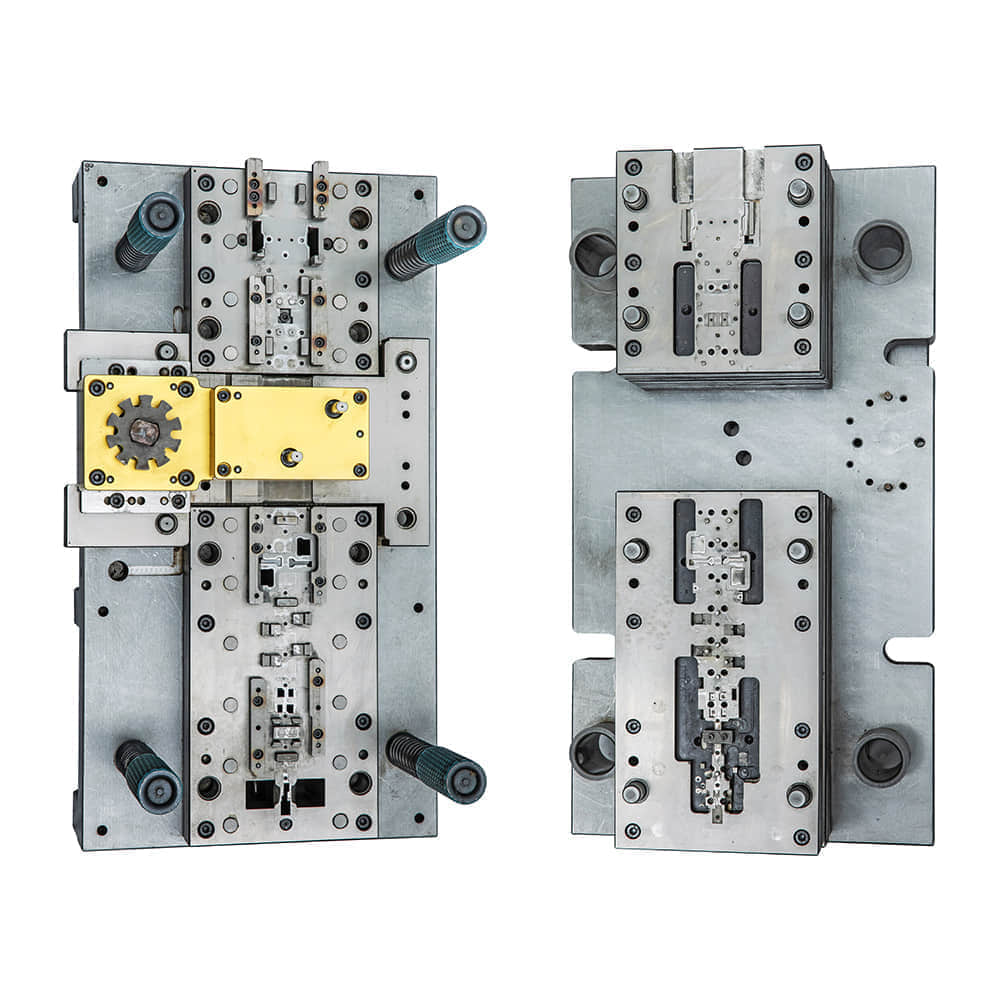

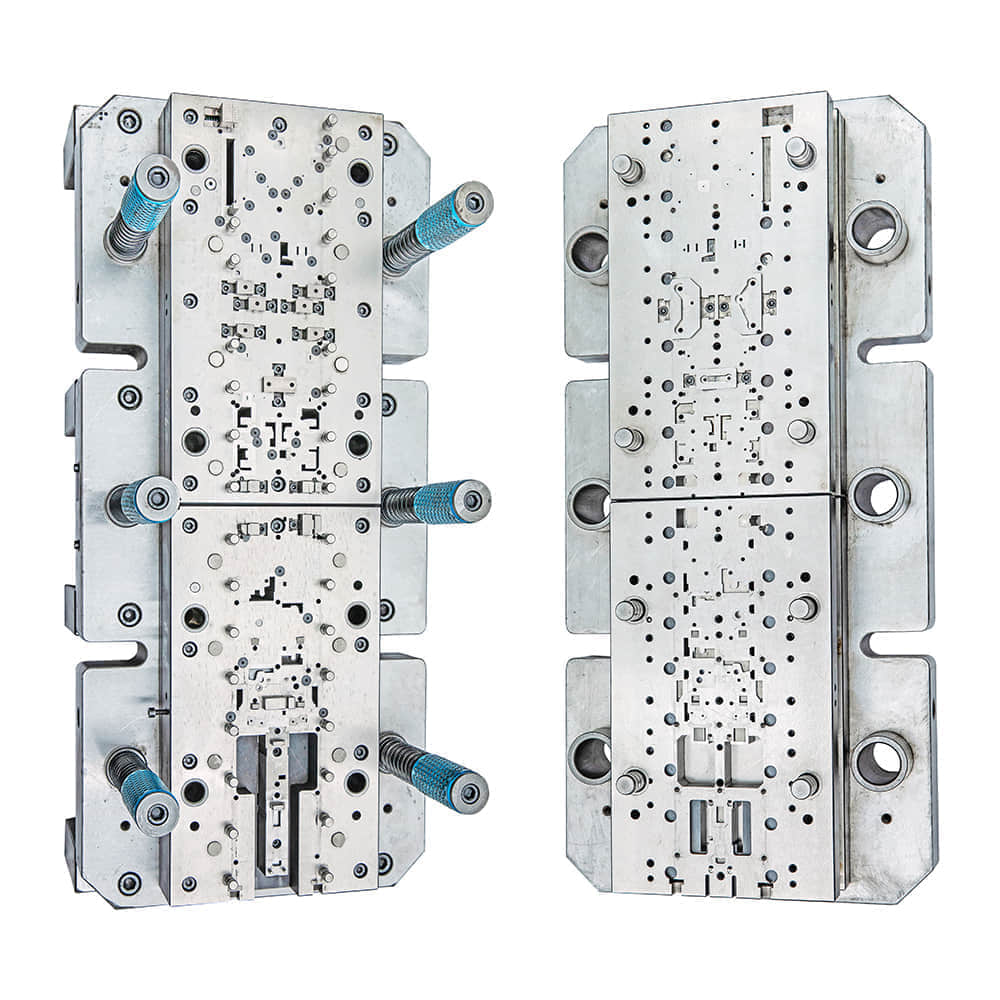

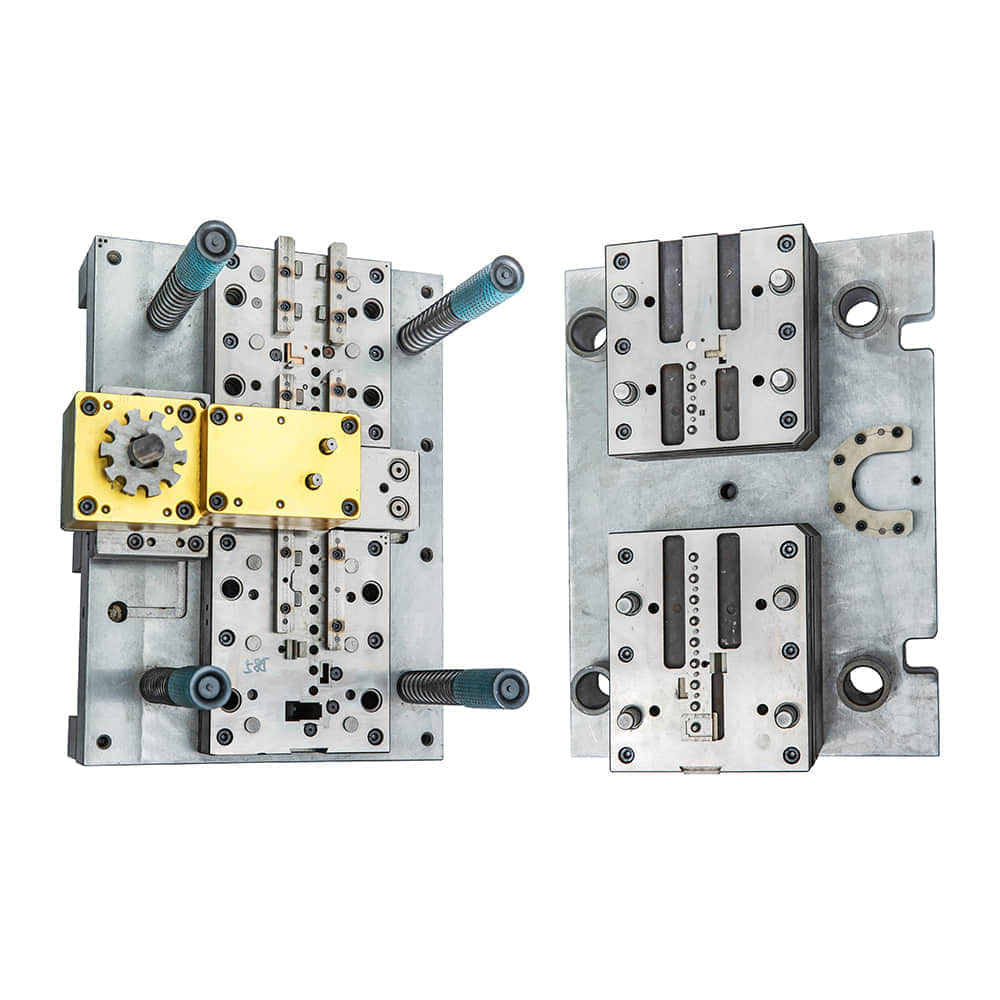

Metal stamping is a manufacturing process that involves placing flat sheets of metal into a stamping press. The press uses a die, which is a specialized tool, to transform the metal sheets into specific shapes through cutting, bending, or forming. The die itself is designed and manufactured by the metal stamping die manufacturer, and its accuracy directly impacts the quality of the finished product. China metal stamping die manufacturers have gained global recognition for their capabilities in producing high-quality dies that cater to various industries, including automotive, electronics, and consumer goods.

One of the defining features of a China metal stamping die manufacturer is their extensive experience and expertise in the field. China has become a hub for manufacturing due to its well-established supply chain, skilled labor force, and investment in advanced technologies. Many manufacturers in China utilize Computer Numerical Control (CNC) machines and other precision equipment to create dies that meet the stringent specifications of their clients. This technology ensures that every die is produced with utmost accuracy, leading to improved production efficiency and reduced waste. The process of manufacturing metal stamping dies involves several stages, including design, prototyping, tooling, and testing. Initially, the design phase is critical, where engineers collaborate with clients to understand their requirements. Advanced software tools are used to create detailed designs that account for the functional and aesthetic aspects of the final product. After the design is approved, prototypes are created to test the functionality of the die before full-scale production begins.